According to data from GGII, the sales volume of industrial robots in China is expected to reach 303,000 units in 2022, a year-on-year increase of about 15.96%, accounting for more than 50% of global sales. China has become the world's largest consumer of industrial robots for nine consecutive years. Ranked first in the world's largest industrial robot market.

However, while the overall development speed of China's industrial robot market is relatively fast, there are still multiple pain points in the application process of industrial robots, such as:

In the machining scene, cutting fluid is generally used, and the oil pollution is heavy, which requires high protection ability of the robot. If the protection ability of the robot is insufficient, an alarm or other failure will occur, which will affect the production efficiency on site. The customer's demand is whether the robot and the supporting control cabinet can have a higher protection level to deal with the harsh environment such as high humidity and high oil pollution on site.

In the scene of rapid material sorting, the on-site installation environment is a steel structure platform. When the robot runs quickly on it, the platform will shake very much, which will have a great impact on the equipment installed on it. The customer's demand is whether the robot can be lighter, occupy less space, and at the same time ensure faster operation in this scenario.

In the material handling scene, such as the PCB industryThe customer's demand is whether the load of the robot can be larger and whether it can cope with a larger moment of inertia.

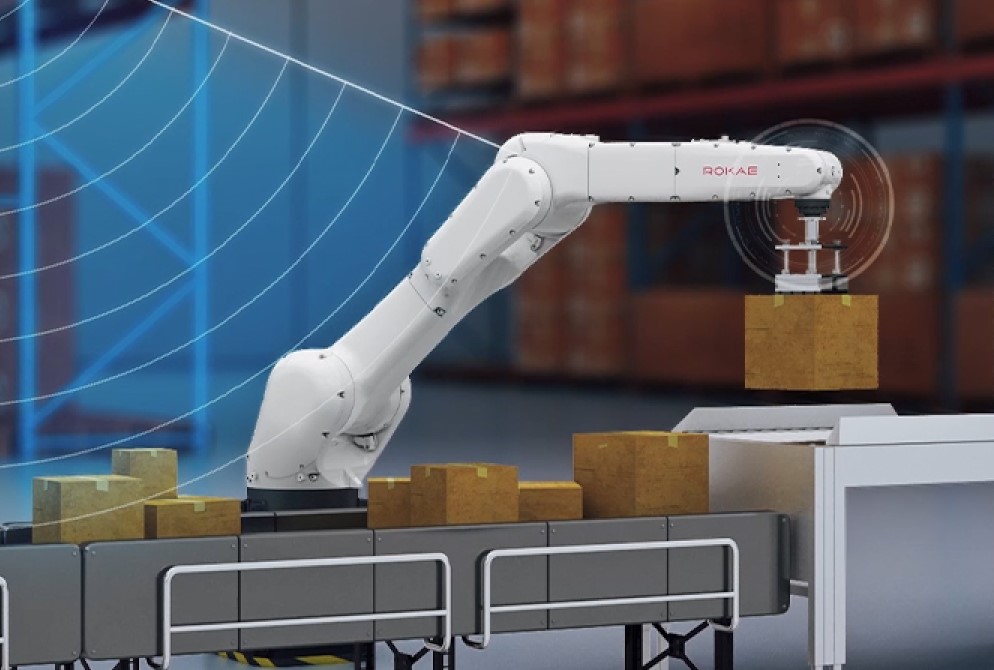

In order to solve the problems that customers care about, through long-term observation of application-side requirements, combined with a large number of scene analysis, and the answers given by customers, ROKAE defined a new product series – ROKAE NB12 series robots, and launched on February 2, 2023 It is officially released to meet the application needs of different scenarios in an all-round way.

Lighter, faster, stronger

NB12 series, a new generation of high-speed robot platform known as «fast and versatile», is a further upgrade of the XB series products.

There are 6 products in the NB12 series robots, 4 of which are six-axis robots, with loads of 10kg, 12kg, and 16kg respectively, and arm spans ranging from 1053mm to 1602mm. In response to the plane handling scenarios in PCB and other industries, ROKAE also customized and developed three-axis robots and four-axis robots, both of which have a maximum working radius of 953mm.

Specifically, the NB12 series has four major advantages:

First, a new design with stronger protection. The NB12 series adopts a full-cast aluminum body design, which is 30% lighter than products of the same level. It is lighter in weight and has smaller support reaction force among similar products, and is more suitable for applications in narrow spaces.

At the same time, the NB12 series adopts a fully-wrapped structure and an upgraded sealing design, the motor cable is built-in, the body has a high protection level of IP67, and is equipped with a high-protection dual-circulation heat dissipation control cabinet of IP54, which can cope with wet and other coolant spray scenarios, reduce the maintenance cost of equipment due to water ingress failures, and improve the efficiency of the production line, to ensure that the robot can cope freely in harsh environments.

Second, it has a compact structure and is easy to deploy. The NB12 series adopts the form of built-in motor and cable, and the structure is more compact. The installation size of the base is only 250x250mm, which is 47% smaller than that of products of the same level. You can choose any installation method such as front mounting, side mounting, and flip mounting, and can be flexibly deployed in small spaces. Improve installation convenience. The NB12 series single-axis rotation range is larger, the working blind area is smaller, and it completely covers the mainstream scene applications of small-load robots.

Third, high-precision and high-speed, high-efficiency production. NB12 series OptiMotion & TrueMotion dual technology guarantee, repeated positioning accuracy of ±0.03mm, 20% increase in operating speed, rapid production and greatly increased production capacity.

Fourth, authoritative certification, escort. The NB12 series has passed a variety of international authoritative certifications, including CE, UL, CR, KCS, EAC, etc. Parts and robots have undergone strict quality inspections to ensure high-quality production.

The NB12 series is not only suitable for application scenarios such as loading and unloading, fast sorting, gluing, polishing and deburring, assembly, testing, etc., its high inertia version is very suitable for high-speed handling of large-sized materials.

The release of the NB12 series is another new start for ROKAE, and the NB25 series will also be launched soon. Its load includes 12kg, 20kg, 25kg, 30kg, 35kg, and the arm span covers 1617mm-2110mm. Compared with the previous generation model, the load The capacity is increased by 25% on average, which can meet the requirements of loading and unloading, deburring, testing, photovoltaic typesetting, sorting, assembly and other scenarios.

Not only that, the industrial prototypes of the NB80 series have also rolled off the production line, with loads including 50kg and 80kg, and arm spans including 2200mm and 2600mm. The NB80 series has the largest load and the longest arm span among robots of the same level, and can easily cope with a wider range of application requirements; high inertia motion characteristics, perfect for large inertia operation scenarios; higher protection level, easy to deal with harsh environments, can be applied up and down material, welding, grinding, handling, gluing and other scenarios.

ROKAE Robot adheres to the platform modularization technology as the basis to create excellent industrial robot platform products. Based on platform-based products, market-oriented, combining product functions, strengthening product advantages, and making smart manufacturing more efficient with faster, more reliable, and more compact product features will bring innovation to the target industry.

Accelerate towards a full range of product matrix

Seven years ago, looking at the Chinese industrial robot market, the industrial robot market for medium and large loads has been dominated by the «big brothers». In addition to the international «four big families» Yaskawa Electric, FANUC, KUKA and ABB, there are Siasun, Efort and other domestic leading enterprises with strong background support.

At that time, light industrial robots not only had a larger market space, but because the objects they manufactured were relatively smaller and more detailed, the precision, accuracy and speed of mechanical control were also higher. Aiming at the field of light industrial robots, it can better utilize its many technical reserves in robot planning, motion, algorithms, etc. Today, 7 years later, ROKAE has not limited to light robots, and has begun to enter the medium and large load robot products.